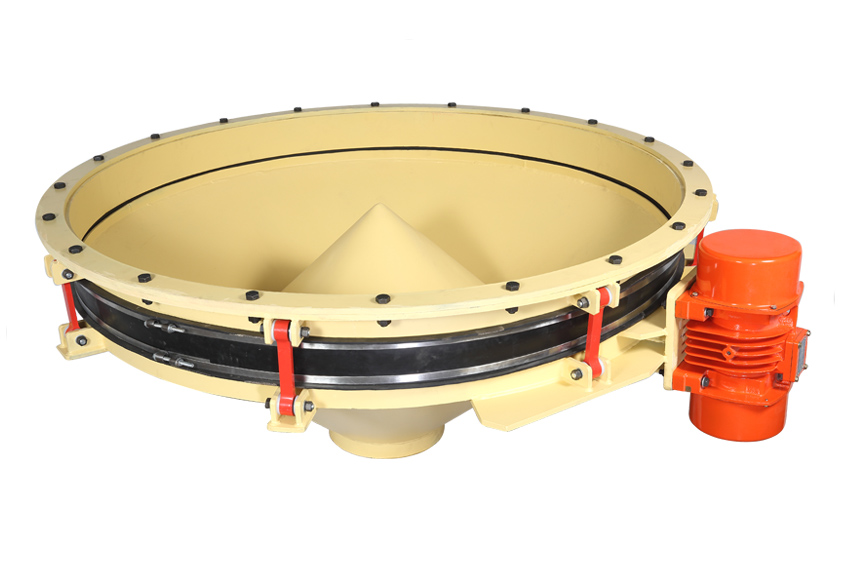

Bin Activator

-

COMPLETE STAINLESS STEEL CONSTRUCTION

Features

- With various sizes to fit under silo bottoms, this unique design features a baffle cone height adjustment to maintain an annular gap ensuring consistent material flow

- A perfectly engineered connection link provides 100% elastic isolation between silo & bin, with no transmitted vibrations to silo body

- Vibrations are transmitted only to the material

- Choice of material of construction can be as per process requirement: Stainless Steel & Mild Steel

An extremely versatile design, capable for handling all types of solid material flow problems like Bridging, Arching, Rat Holing and Flushing. Also known as Vibratory Bin Bottom, is widely used in several industries to attain a continuous and controlled flow of the material. Available in various sizes and construction material, can be availed at affordable rates.

Advantages

Sizes available

600 mm

900 mm

1200 mm

1500 mm

1800 mm

2000 mm

-

COMPLETE MILD STEEL CONSTRUCTION

-

TYPICAL INSTALLATION

Application Industries

Coal | Carbon | Cement | Calcium Carbonate | Detergents | Food | Fertilizer | Flour | Glass | Iron Ore | Minerals | Mica | Polymers | Paints Pigments | Plastics | Sugar | Spices | Sand